Analysis of a Roll Forge

Group of 4 : 1 month

Background

For Engineering Design II, we were tasked with analyzing a roll forge. The analysis involved the following steps:

-

Modelling forces

-

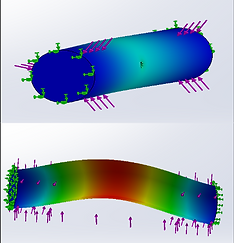

Modeled the process that would produce the target connecting rod geometry using an FEA simulation and mathematical calculations

-

Simulation details

-

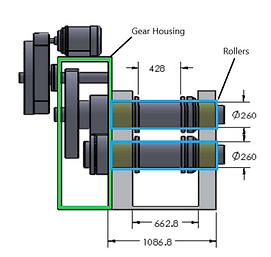

Matching dies were semi-cylindrical, covering180° of the roll

-

4-5 passes per preform

-

Radial force applied to the workpiece and torque were tracked with time

-

The last pass generates the greatest force and torque values

-

-

-

-

Cycle time and productivity

-

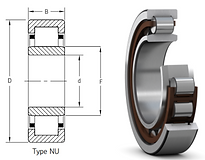

Determined the bearing reaction forces, factor of safety, wear and fatigue, potential, gear failure, and determine an appropriate material based on these conditions:

-

4 passes are used to create one preform

-

Assume each pass generates the same radial force and torque profile

-

The cycle time is 10 seconds

-

On average, the roll forge is run 8 hours a day for 260 days

-

-

Task Distribution

During our first few meetings, my group decided to calculate the force location and distribution together before dividing the work. Each member attempted the calculations on their own and after coming to an agreement, the project tasks were divided. I worked on the FEA simulation, bearing force distribution, bearing recommendation (for purchasing), roller deflection, and static failure

Future Work

If I could go back in time and give myself advice on how to improve the work completed:

-

Narrow the search of the materials in MatWeb based on the original calculations

-

Change the dimensions of the components

-

Run an FEA simulation on the bearings as well