Intrepid Robot

Group of 3: 11/22- 12/08 2021

Background

For ME30: Electromechanical Systems & Robotics I, we were tasked with building a robot. The robot was placed in the first floor of the engineering building and had to do the following in 15 minutes:

-

High-five a TA (target hand heigh 105.5-107 cm)

-

Travel to the Mechanical Engineering office located in the second floor

-

Should be powered by batteries and be remotely controlled (through WiFi)

Task Distribution

Individual

Group

-

The majority of the project was completed with the three of us meeting together. We would teach each other what we knew or had learned from online resources and would sit together, staring at the same laptop while writing the code and creating a PCB

-

Discuss research findings

-

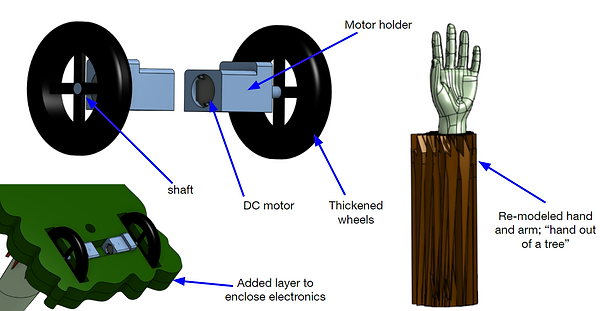

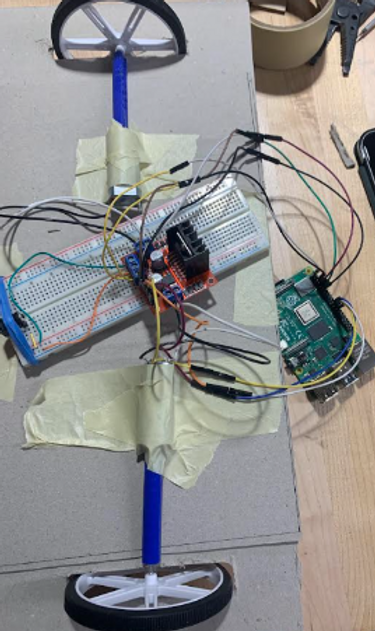

Brainstorm ideas and general design breakdown (i.e. how to physically connect the wheels to the DC motor and the layout of the electronics)

-

Code the backbone

-

Meetings were set up weekly where we would discuss what we wanted the code to do and would bounce ideas off one another for how to implement the ideas into actual code (none of us had much exposure to Python)

-

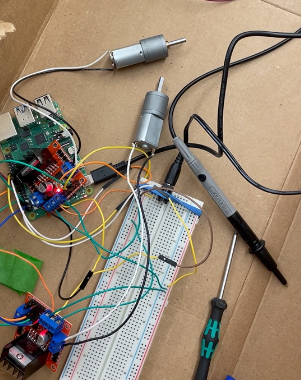

Wiring

-

Assembly

-

Research

-

Motor

-

Power (input)

-

Robot wheels

-

Microcontroller vs microprocessor

-

-

Self-study

-

Python language

-

How do we go from python to moving wheels

-

-

-

Connecting my Pi to Tufts wireless

-

Design motor holder and L-brackets

-

Lasercut is the base for the robot

-

Code re-do

-

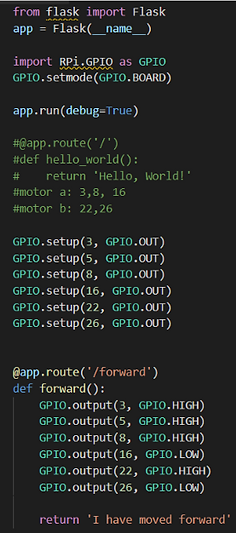

The Pi originally used was corrupted and all code was lost. I began rewriting the code needed to move the wheels while another team member finished the re-written code that read the URL used to remotely control the Pi

-

Research

-

Motor (Geared DC motor)

-

High torque and efficiency: our robot needed to carry a relatively large weight and it had to travel a large distance in under 15 minutes BUT it also needed to be compact

-

Speed variation: in order to get to the second floor, the robot needs to get on an elevator and take sharp turns

-

-

Microprocessor (RaspberryPi 4)

My team and I chose a microprocessor over a microcontroller:

-

The robot needed to be remotely controlled

-

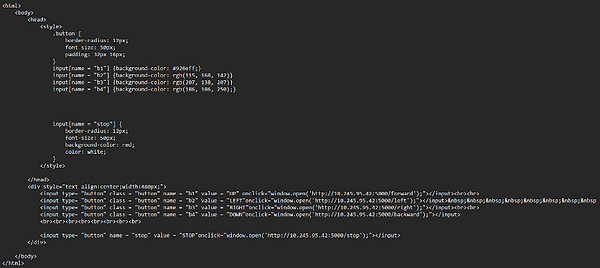

A website was used to move the robot and the Pi is able to browse the internet

-

-

Task complexity

-

A microprocessor would allow us to run the motors while also commanding the robot in what direction to move through the internet

-

Design/ Prototype

Future Design

-

Code

-

The way the buttons in the HTML code were made adds a tab every time they’re pressed. This meant that we would have to quickly jump back to the original website (with the four buttons) after every move the robot made

-

Instead of decreasing the speed of one of the motors during turns, GPIO pins were set to low

-

Including the option to decrease the speed

-

-

Physical model

-

Enclose the electronics

-

Thicken the wheels

-

Design and order a PCB through OSH park

-

Overall, make the design more appealing

-