Electric Knife Teardown

Group of 3 : 1.5 months

Background

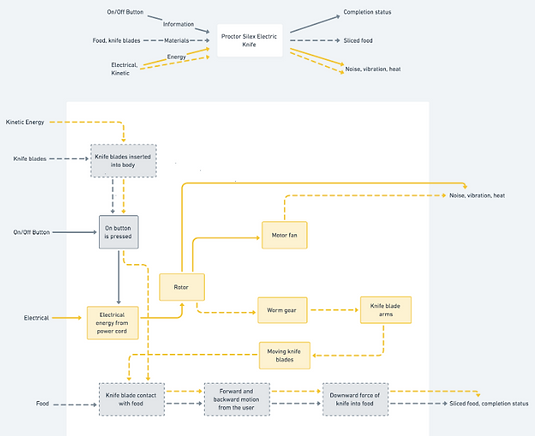

For ME40: Engineering Design I, each student was given a product to teardown. The course is open to Mechanical Engineering, Human Factors, and Engineering Psychology students. I was the only Mechanical Engineering in my team and thus worked the most on CAD modeling. Due to COVID restrictions, access to the machine shop and maker spaces were very limited. After this project was completed, all information was exchanged with other teams to re-model a (different) product for users with Parkinsons disease.

In groups of three, an analysis and re-modelling of the product teardown was completed with the following goals in mind:

-

Develop basic knowledge of hand tools

-

Develop insights about users and their experience with a product

-

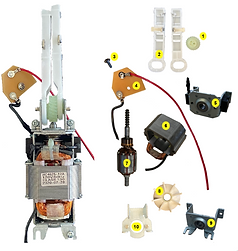

Gain knowledge of how consumer products function and are constructed (including materials and manufacturing)

-

Think about the choices designers make in creating products that respond to customer needs

-

Understand the role of machine design elements in mechanical design

User Experience

User Centered Design

-

Researched public information on the product and the intended audience

Packing

-

Documented the materials used, how a user would first interact with the product, and what instructions are provided

First use

-

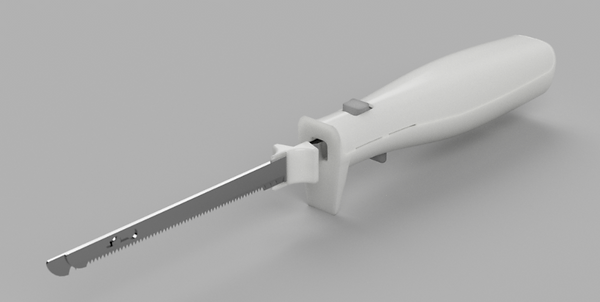

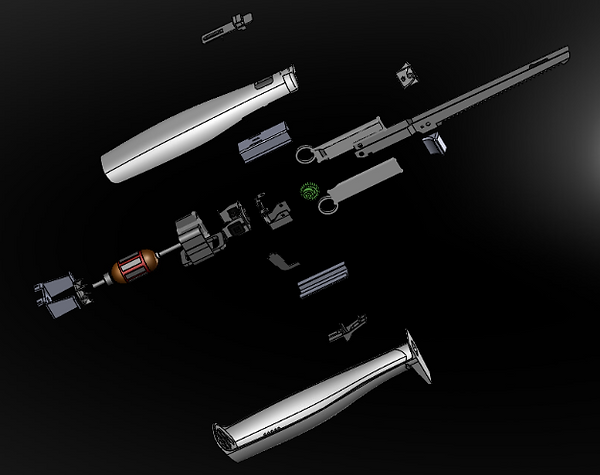

Documented the assembly and setup processes and the canonical use

Knowledge Elicitation/Observation

-

Observed someone outside of the team using the product in a Hierarchical Task Analysis

Off-nominal use

-

Reviewed the use of the product with respect to tolerance to off-nominal usage

Concept of Operations (CONOPS analysis)

-

Created a document describing the characteristics of the system from the perspective of a user

Design and function